Products For Semiconductor/FPD Applications

POINT

We provide high quality chemicals at lower costs.

Adopting overseas products can

contribute to dealing with BCP.

LOT Vacuum develops, manufactures and sells vacuum pumps for semiconductor and FPD

manufacturing processes.

LOT Vacuum is the No. 1 manufacturer with a market share of more than 80% in CVD processes in the Korean

semiconductor market, with the sales record of more than 20,000 units worldwide.

POINT

A hybrid vacuum pump that combines screw and roots types has been developed.

Its high

displacement capacity reduces noise and power consumption.

WCS M300: Automated all-in-one VPD-ICP-MS system

This system is capable of high sensitivity analysis of metal contamination on wafers at

sub-ppt level.

This is a fully automated VPD-ICP-MS system that automates everything from sampling,

pre-treatment to post-cleaning with a high level of safety.

POINT

It is a system that integrates Sampling/VPD/ICP-MS in one space-saving housing.

Automated

operation is achieved, from pre-treatment through to post-treatment, due to ICP-MS system calibration, automatic

cleaning of sample tubes, self-diagnosis of cleanliness, and automatic preparation of scanning and cleaning

solutions.

OCIM: On-line chemical impurity monitoring system

This system is capable of on-line/real-time analysis of metallic impurities in chemicals, UPW

and gases at sub-ppt level.

This is a fully automated sampling and analysis system that is safe and prevents

sample contamination.

POINT

Everything from sampling, pre-treatment, measurement through to post-cleaning can be done

fully automatically with this on-line monitoring system.

Up to 60 channels can be measured with one main unit.

Leak sensors that can be used for the interlock system

and gas detectors are equipped.

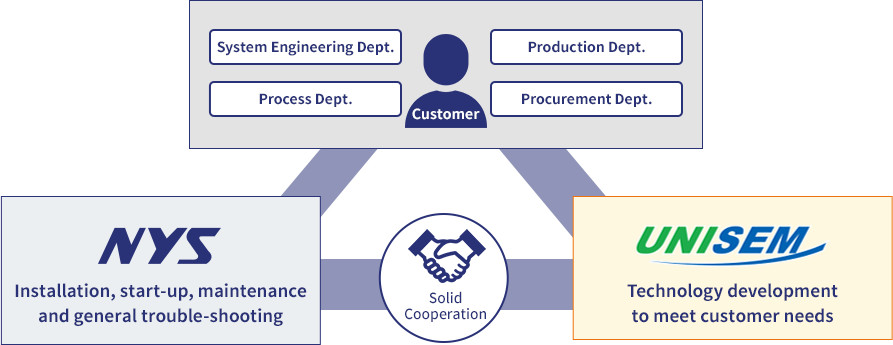

We provide scrubbers and chillers of UNISEM, a leading manufacturer in Korea.

Back-Up function

Low cost

Space-saving

Energy-saving

Compatible with all gases

Superb maintenance services

UNISEM is a leading manufacturer of scrubbers and chillers for semiconductor and LCD processes

in Korea.

Especially for scrubbers, they offer a wide range of product types such as combustion, plasma, heater and hybrid

to meet various characteristics of production process and process gas, and the amount of waste gas treatment, etc.

Several hundred units have been installed in Japan, and the flexibility to deal with customized designs is highly

regarded.

POINT

With scrubbers, we excel in CVD processes where large capacity is required and a large amount

of by-product is produced.

We are also focusing on R&D of next generation equipment for both scrubbers and

chillers, targeting energy saving and size reduction.

We provide optimal equipment designs and coherent

after-sales servicing from system start-up to maintenance work through collaboration of UNISEM’s experience and

local support by NISHIMURA CHEMITECH.

Scrubber

Chiller

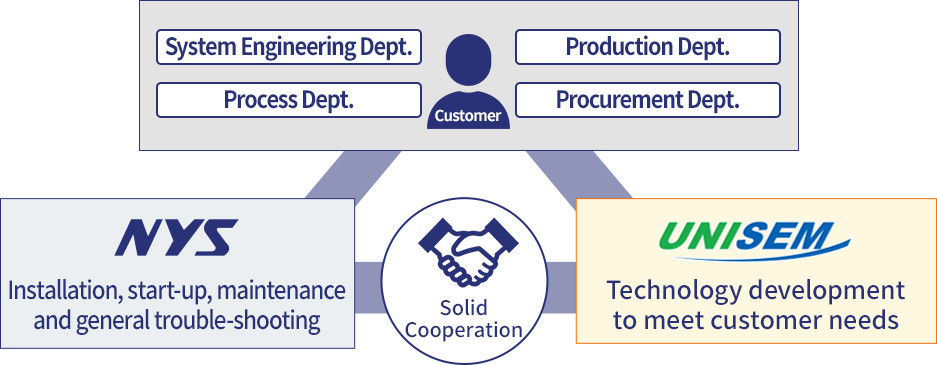

SUPPORT

Support structure

| Sales Gr. |

*Mediation & negotiation with customers/UNISEM *Determining specifications and handling trouble calls, etc. |

|---|---|

| F/E Gr. |

*System startup, servicing, maintenance, troubleshooting |

| UNISEM resident staff |

*Detailed feedback to the home country |

| Sales Gr. |

*Overall support required to expand business in Japan |

|---|---|

| Electrical/Design Gr. |

*Hardware and software specification design *Design proposals for retrofit/improvement |

| R&D Gr. |

*Research and experiments to improve abatement efficiency and reduce running costs, mainly. |