Design & manufacturing of

OUR MISSION

1. To be an engineering group who can create and propose new

technologies and high value-added equipment

2. To design and manufacture original equipment based on the concept of “Face and solve

problems that arise on site” and to contribute to tackling such users’ challenges as “cost reduction”,

“quality improvement”, “longer facility life” and “automation”

ADVANTAGES: Slurry/Chemical Delivery Systems: Design & Manufacturing

Proposal of equipment customization

We offer design proposals that raise the functionality of equipment to the next level. Contact us for completely original designs.

Total cost reduction

We offer proposals for performance improvement to achieve total cost reductions.

Low trouble rate

Our design policy is to meet users’ needs with safety-first concept. Our multi-stage check mechanism can prevent problems from happening.

Quick & Fast Response

We aim to respond in about 1/2 the time of other companies.

SERVICES

Value to Offer

Slurry dilution & delivery system (Slurry Supply)

Chemical dilution & delivery system (Chemical Supply)

Drum cabinet for undiluted chemicals

Chemical supply (Special unit)

POU mixing system *in development

Contact us for details.

CHEMICAL MIXING METHOD

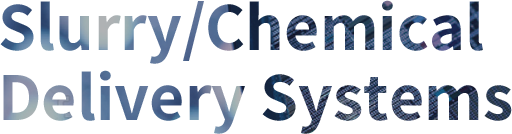

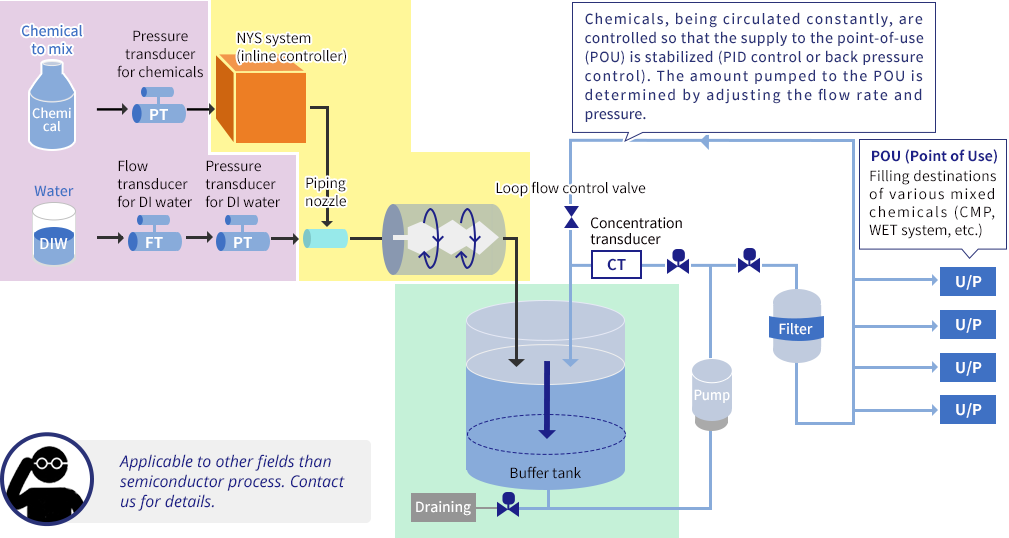

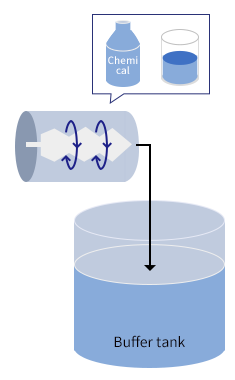

Example: An in-line mixing system developed in-house

The “Mixer” and “Tank” functions are both mounted in the piping.

The “Mixer” and “Tank” functions are both mounted in the piping.

Conventional methods …

mix chemicals and water in one tank.

Disadvantages

method …

mixes chemicals and water in the piping before they enter a tank.

mixes chemicals and water in the piping before they enter a tank.

Advantages

(1) Space saving

Mixing and stirring can be done simultaneously in the piping, and the number of tanks and the footprint can be minimized.

(2) High-precision mixing

No need to worry about impurities getting into the tank as mixing is done in the piping without being exposed to the outside air.

(3) High-efficiency operation

Since mixing processes are completed before the fluids go into the tank, the mixed

fluid in the tank can be replenished even during a dispensation process.

Also, chemical

concentration can be easily changed.

(4) Improved productivity

Continuous monitoring of concentration during dispensation processes ensures a

stable supply.

Mixing processes can be done continuously (with real-time monitoring function).

(5) Lower cost

Achieving (1) through (4) results in total cost reduction.

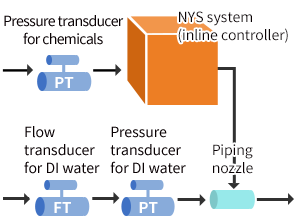

How we achieve high-precision mixing

The key to improving the mixing accuracy is to pay close attention to the accuracy of equipment used in the

process before mixing chemicals and water.

NISHIMURA CHEMITECH jointly develop such equipment with equipment manufacturers as system equipment,

pressure gauges, flow meters and piping nozzles to improve the equipment accuracy.

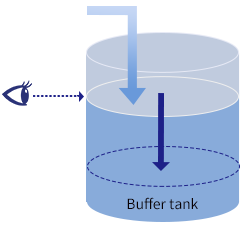

Replenishing operation

Mixed fluid is stored in a tank and then dispensed into POUs (chemical bottles, etc.).

We offer a

function to adjust the amount of fluid stored in the tank: when the mixed fluid volume decreases, a sensor

detects the drop in the fluid level to start a replenishing mixing to bring the level back to a constant

level.

CUSTOMER SERVICE

A request from a company who seeks a solution proposal type of development

“To develop a cutting-edge product, we want you to join us from the very start and give advice.”

A request from a company who is interested in original customization

“We want to increase productivity by customizing the equipment to suit our company’s needs.”

A request from a client who wishes to convert their technology

“We want to make the most of our semiconductor equipment manufacturing technology in a new field.”

OUR HISTORY & VISION

Learn about the background of our design/manufacturing division as well as our vision for the future.

LOCATIONS