Chemical production

OUR MISSION

To bring out products of unrivalled high quality and price to the world through manufacturing chemicals that meet requirements and exceed expectations of customers.

ADVANTAGES: Chemical production

We have lots of experience working with world-class manufacturers.

As an OEM of a major chemical manufacturer, we are able to provide world-class chemicals to the world’s leading semiconductor device manufacturers.

We can accommodate completely original quality control requests.

Our capacity to meet world-class requirements on specifications and quality enables us to meet any quality control item.

EQUIPMENT INTRODUCTION

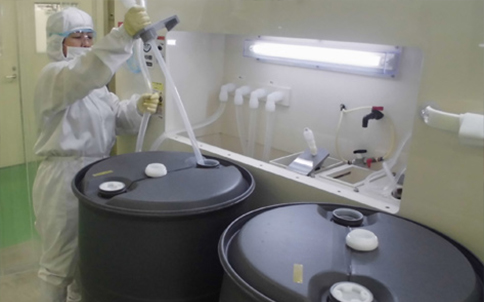

EquipmentUPW equipment

EQUIPMENT INTORODUCTION

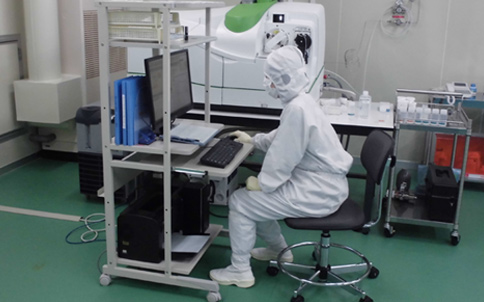

EquipmentAnalysis equipment

| Machine Name | Purpose |

|---|---|

| ICP-MS | Trace metal analysis. Lower detection limit: about 10 ppt (may vary depending on the element to be

measured) The NYSP-owned system’s sample introduction system: capable of measuring hydrofluoric acid sample |

| Automatic potentiometric titration | Concentration measurement of acidic and alkaline liquid samples (neutralization titration) |

| Spectrophotometer | UV-visible spectrophotometer with a resolution of 1 nm (measurement wavelength range: 190-1100 nm) |

| Tabletop pH meter | pH measurement from strong acid to strong alkaline by performing internal calibration with a pH standard solution (JIS) |

| Electric conductivity meter | 0-20 mS/m electrical conductivity measurement (the measurement range changeable by replacing the electrodes) |

| Oscillation-type density/specific gravity meter | Specific gravity measurement of liquid samples in general |

| Surface tensiometer | Surface tension measurement of liquid samples (Can be set to any temperature) |

| ICP-OES | Trace metal analysis. Lower detection limit: about 10 ppb (may vary depending on the element to be measured) |

MANUFACTURING ENVIRONMENT

Analysis room: Class 1000

Filling room: Class 1000

GROUP COMPANY OVERVIEW

| Corporate Name | NYS PRECISION CO., LTD. |

|---|---|

| Head Office | 1-8-28 Aosaki, Oita-shi, Oita, Japan |

| Representative Director President | Masayuki Nishimura |

| Date of Establishment | March 1, 2006 |

| Capital | 20 million yen |

| Parent Company | NISHIMURA CHEMITECH CO.,LTD. (100% owned) |

| Outline of Business | Manufacturing on commission of high-purity chemicals for semiconductors |

Building Overview

| Site area | 4,491m2 (1,360 tsubo) |

|---|---|

| Total floor area | 5,815 m2 (1,762 tsubo) |

| Main building (manufacturing building) | 5,167 m2 |

| Ancillary building (power/pure water building) | 648 m2 |

ISO Certifications and Other Authentications

| Quality & environmental certifications |

(1) June 2011 – ISO 14001 certified (2) July 2012 – ISO 9001 certified (3) September 2015 – TS16949 JQA audit conducted |

|---|---|

| Audit certifications from customer lines |

(1) 2012 – Audit certification from a major Taiwanese semiconductor manufacturing company line (2) 2014 – Audit certification from a major U.S. semiconductor manufacturing company line (3) 2015 – TS16949 audit conducted from a major Taiwanese semiconductor manufacturing company line (4) Others – Audit certifications from two major Japanese semiconductor manufacturing companies’ lines |

Quality Management System

| Internal audit | Once a year (in-house), once every 3 months (production lines) |

|---|---|

| Customer internal audit | End-user audit once every 3 months or audit each time as it happens |

| Customer line audit certifications | MSA management, external calibration and internal calibration |

| Introduction of quality management system | SPC management (alert line setting), manufacturing process management, and traceability management |

| SPC SPC level view |

Once a month (in-house), every 3 months (customer) (high level) |

LOCATIONS