Analysis result report

-

Array

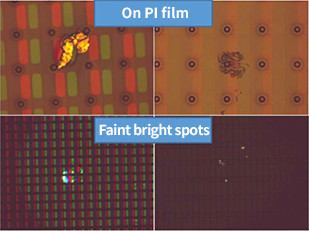

Microphotographs of the array and CF surface (location and classification)

-

Cell

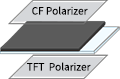

Collection of polarizing plate debris and its microphotographs (location and classification)

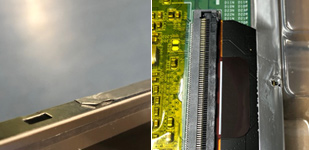

Microphotographs of the glass surface (flaws, etc.) (location and classification)

-

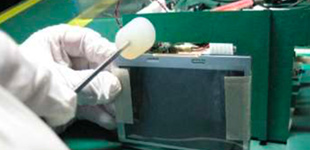

Module

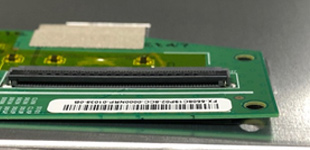

Microphotographs of FPCs, etc.

Collection of backlight debris and its microphotographs (classification)