News & Topics

26/11/2024

NISHIMURA CHEMITECH CO., LTD. to exhibit in SEMICON Japan 2024

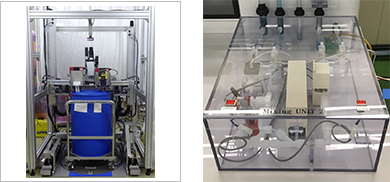

①Slurry/chemical dilution & delivery system

At point-of-use, this equipment mixes DI and undiluted slurry+additive [H2O2] etc… and delivers it. [multi-chemical mixing]

Consentration at delivery point can be changed easily, consentration change during delivery is also possible. Without worries with expiration date or degradation over time, pure slurry can be delivered.

②Drum cabinet complete automation system [D/C automation equipment]

Complete automation of drum exchange/chemical delivery has solved problems caused by conventional manual drum exchange [drum drop-off,/fall down, wrong set up, chemical loss]

Drum exchange [available for 24 hours] enables stable undiluted chemical supply, reducing loss of cost/time in drum exchange and increasing operation efficiency.

Introducing NYS slurry/chemical delivery system [featuring in-line mixing], integrating high presicion/high magnification dilution & mixing system

and LPC monitor and chemical monitor on line.

By integrating [lab analysis equipment level] LPC measurement and chemical consentration measurement on line, managing data trend makes it possible to suppress issues caused by delivered slurry/chemical, leading to higher accuracy consentration control.

UNISEM is Korea’s leading scrubber/chiller manufacturer for semiconductor/LCD manufacturing process.

There is a variety of scrubber line up such as burn-wet or plasma,

with sales track record of over 500 units to Japanese device manufacturers.

As more units are sold, Nishimura Chemitech is tightening relathionship with UNISEM and acts as 1 stop shop for set up, service, maintenance, and on site support.

LOT VACUUM is Korean dry vacuum pump manifacturer targetting semiconductor/LCD/solar power industry.

Since most of semiconductor/LCD fornt end manufacturing is processed under vacuum,

vacuum pump is used for creating vacuum by deairing various materials [including gas] in a certain space.

This company’s pump is screw type vacuum pump, in which a couple of the same shape screws are meshed and rotating to draw/discharge gas.

Compared with roots type employed by competitor pump manufacturers, less parts count and bigger exhaust volume.

Connected to vacuum pipe before pump, toxic / flammable gas can be processed to safe gas by this system.

In Pipe Predictive Maintenance, this system can preveent heating/ignition/explosion of process byproduct such as ZrO,HfO,TiO, therefore this system is widely adopted in the applicable processes from evironmental safety standpoint.

Features

Processing toxic / flammable gas into safe gas

Decomposition / exhaust of byproduct

Minimize byproduct particle size

SEMI-TS, founded in 2014, started AMHS solution busines [indispensable for semiconductor manufacturing process],

clean conveyer for 300mm FAB / E84 sensor business / smart purge system / smart OHT development etc…

Water soluble protective film for laser process

Water soluble protective film for laser process is aqueous polymer solution. By spin coating on laser processing surface,

It can extremely decreases debris on the surface, contributing to device reliability improcement.

Dicing additive

Dicing additive is aqueous polymer solution. It can disperse wafer debris generated in blade dicing,

preventing debris from piling up on wafer surface, leading to reduce corrosion/contamination risk.

In order to develop high performance/low cost SWIR image sensor,

it offers quantum dot product and technical services suporting image sensor, sensor material and semiconductor manufacturing.

Compared with existing SWIR technoclogy, it can extremly reduce cost and revolutionalise SWIR product market.

This product is packing material designed for clean packaging [qualified by AMAT, fully manufactured in ISO-Class 5 clean room].

Suitable for packing of semiconductor manufacturing equipment/part, semiconductor grade high purity material and wafer.

◆Line up:class 100 PE/Nylon clean bag, PE/ESD protection bag, pure/compound nylon bag, aluminum foil bag,