News & Topics

30/11/2025

NISHIMURA CHEMITECH CO., LTD. to exhibit in SEMICON Japan 2025

Nishimura Chemtech’s long-standing commitment to POU mixing technology has evolved into new applications through integration with measurement instruments.

This system integrates dilution and analysis functions, enabling real-time monitoring of the supply (mixed) chemicals state. It provides an innovative solution that handles everything from verifying chemical delivery status to automatic data collection in a single process. It offers flexibility for use across diverse processes, from chemicals manufacturing scenes to semiconductor device production processes, contributing to process stabilization, advanced quality control, and improved traceability.

Experience our next-generation system—integrating dilution, analysis, and monitoring—which further enhances the value of POU mixing.

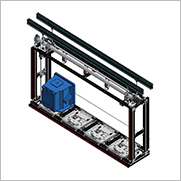

Nishimura Chemtech’s “Evolved Drum Cabinet System” incorporates new technologies into its long-established automated drum cabinet system, enabling adaptation to a wider range of installation locations and environments.

This system was developed based on research advancing reliability and operability by further refining the conventional actuator method.

Furthermore, by adopting a robotic approach, the system has evolved into a structure that flexibly accommodates diverse constraints—such as installation environment, conditions, transportation routes, and methods—that were previously challenges. This enables deployment in various sites and significantly increases operational flexibility.

Our proprietary inspection program precisely locates lead frame products and detects minute defects with high accuracy.

Correction functions for each lead component prevent over-detection, ensuring stable inspection.

Furthermore, by accumulating and verifying product data,we continuously evolve inspection algorithms and improve accuracy.

This new type of inspection machine was born from customer needs.

UNISEM is Korea’s leading scrubber/chiller manufacturer for semiconductor/LCD manufacturing process.

There is a variety of scrubber line up such as burn-wet or plasma, with sales track record of over 500 units to Japanese device manufacturers.

As more units are sold, Nishimura Chemitech is tightening relathionship with UNISEM and acts as 1 stop shop for set up, service, maintenance, and on site support.

LOT VACUUM is Korean dry vacuum pump manifacturer targetting semiconductor/LCD/solar power industry.

Since most of semiconductor/LCD fornt end manufacturing is processed under vacuum,vacuum pump is used for creating vacuum by deairing various materials [including gas] in a certain space.

This company’s pump is screw type vacuum pump, in which a couple of the same shape screws are meshed and rotating to draw/discharge gas.

Compared with roots type employed by competitor pump manufacturers, less parts count and bigger exhaust volume.

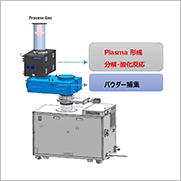

Connected to vacuum pipe before pump, toxic / flammable gas can be processed to safe gas by this system.In Pipe Predictive Maintenance, this system can preveent heating/ignition/explosion of process byproduct such as ZrO,HfO,TiO, therefore this system is widely adopted in the applicable processes from evironmental safety standpoint.

Features

・Processing toxic / flammable gas into safe gas

・Decomposition / exhaust of byproduct

・Minimize byproduct particle size

We provide essential materials for clean environments—including clean suits, clean hoods, safety shoes, and shoe covers—for semiconductor and medical factories. These are manufactured and quality assured in-house at our Taiwan facility.

We offer flexible solutions from small batches to large-scale deployments.

Leveraging over 20 years of cleaning expertise in Taiwan, we manage cleaning, inspection, and repairs entirely in a dedicated Class 1-compliant environment.

We consistently suppress particulate matter, static electricity, and fiber degradation, maintaining the cleanliness, performance, and comfort of clean suits.

Water soluble protective film for laser process

Water soluble protective film for laser process is aqueous polymer solution. By spin coating on laser processing surface,It can extremely decreases debris on the surface, contributing to device reliability improcement.

Dicing additive

ダDicing additive is aqueous polymer solution. It can disperse wafer debris generated in blade dicing,preventing debris from piling up on wafer surface, leading to reduce corrosion/contamination risk.

In order to develop high performance/low cost SWIR image sensor,it offers quantum dot product and technical services suporting image sensor, sensor material and semiconductor manufacturing.

Compared with existing SWIR technoclogy, it can extremly reduce cost and revolutionalise SWIR product market.

This product is packing material designed for clean packaging [qualified by AMAT, fully manufactured in ISO-Class 5 clean room].

Suitable for packing of semiconductor manufacturing equipment/part, semiconductor grade high purity material and wafer.

◆Line up:class 100 PE/Nylon clean bag, PE/ESD protection bag, pure/compound nylon bag, aluminum foil bag,and consumables. As qualified vendor for AMAT, ASMC, NAURA and so forth, adoped by many suppliers to those manufacturers.Planning to be qualified by LAM research as well.

SEMI-TS, founded in 2014, started AMHS solution busines [indispensable for semiconductor manufacturing process],clean conveyer for 300mm FAB / E84 sensor business / smart purge system / smart OHT development etc…